WFEL awards Boxer Armoured Vehicle sub-contract to Midlands Precision Engineering Company

In a further roll-out of the UK supply chain for manufacture of the Boxer Armoured Vehicles for the British Army, WFEL has contracted with Nasmyth Group for the supply of precision machined and fabricated components.

This ten-year Long Term Supply Agreement will ensure the provision of vital precision-manufactured elements for the highly mobile, wheeled armoured combat vehicles. The Boxer vehicles combine long distance road deployment with all-terrain mobility and bring new capabilities to the British Army.

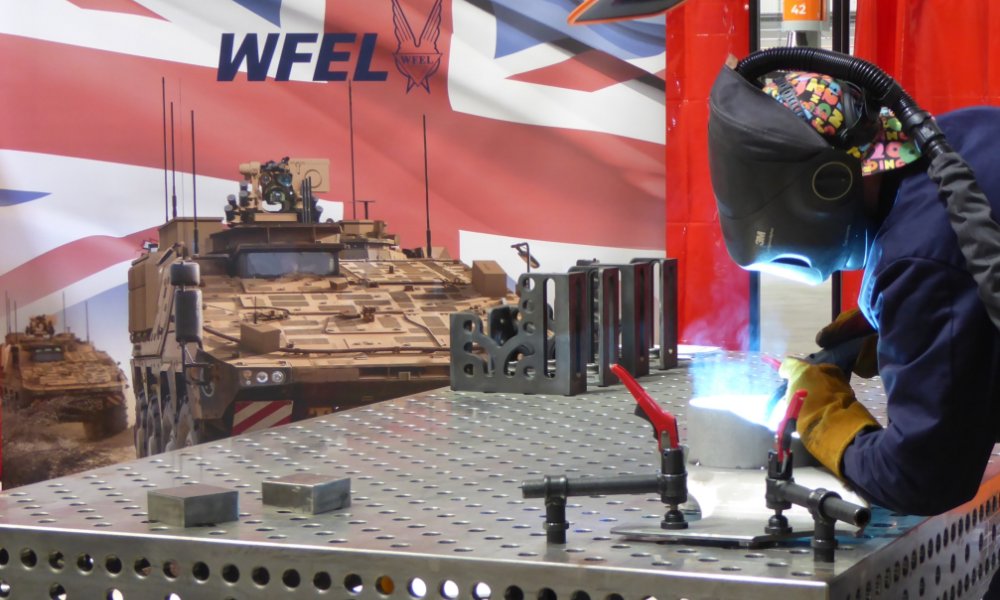

WFEL is a key partner in delivering these state-of-the-art vehicles to the British Army, with fabrication and assembly of the Boxers taking place at WFEL's brand-new facility in Stockport. WFEL is developing a robust supply chain throughout the UK to support the £3.2bn Boxer Programme, which is helping to support regional economic growth and job creation and sustainment and contributing to levelling-up opportunities.

The Boxer base platform, with its interchangeable Mission Modules, can cover a range of capabilities, from infantry personnel transportation around the battlefield to highly equipped mobile medical facilities. The British Army will take delivery of more than 500 Boxer vehicle variants, including infantry carriers, specialist carriers, command vehicles and ambulances.

Ian Anderton, WFEL Managing Director, said, “We warmly welcome Nasmyth Group into our expanding UK Boxer family and look forward to developing a close partnership as we collaborate to successfully deliver this exciting project for the British Army."

Peter Smith, Chairman and CEO of Nasmyth Group, commented: “For the defence markets, Nasmyth Group manufactures a wide range of complex components for a variety of military applications. We look forward to working with the team at WFEL to manufacture component parts for the Boxer Armoured Vehicle Programme.”